Metal Effect Powder Coating

Intshayelelo ngokubanzi:

Inokubonelela ngeengubo zentsimbi zentsimbi zohlobo oluxubileyo, uhlobo olucocekileyo lwe-polyester kunye nezinye iintlobo ze-resin, i-thermosetting powder coatings eneempawu ezibalaseleyo zoMzimba, iipropati zeekhemikhali kunye neempawu zokuhombisa. Ifanelekile ukusetyenziswa kwangaphakathi okanye ngaphandle. Le mveliso inesiphumo sokuhombisa imbonakalo ekhethekileyo kunye neyobunewunewu, esetyenziswa ngokubanzi kwindawo yokugquma izinto zombane zasekhaya, izixhobo zokupheka, amaqokobhe esixhobo, izixhobo ze-electromechanical, ifenitshala yangaphakathi, iinxalenye zemoto, njl.

Uluhlu lweMveliso:

Ukubonelela ngamagqabantshintshi (80% ngasentla), isemi-light (50-80%), iglasi engenanto (20-50%) kwaye akukho ukukhanya (20% ngezantsi) iimveliso okanye kwiimfuno

Iinkcazelo Ngeempawu:

Umxhuzulane okhethekileyo(g/cm3, 25℃): 1.4-1.7

Ukuhanjiswa kobungakanani besuntswana: 100% ngaphantsi kwe-100 micron (Inokulungelelaniswa ngokweemfuno ezikhethekileyo zokugquma)

Iimeko zokwakha:

Unyango lwangaphambili: Unyango lwangaphambili olwahlukeneyo lwesubstrates ezahlukeneyo (unyango lwephosphating, unyango lokuqhushumba kwesanti, unyango lokuchama oludutyulweyo)

Imo yokunyanga: ukwakhiwa kompu omileyo owenziwe ngesandla okanye ozenzekelayo

Iimeko zokunyanga: 200 ℃ (ubushushu bokusebenza), imizuzu eyi-10

Ukusebenza kokwaleka:

| Into yovavanyo | Umgangatho wokuhlola okanye indlela | Iimpawu zovavanyo |

| ukumelana nefuthe | ISO 6272 | 50kg.cm |

| uvavanyo ikomityi | ISO 1520 | 8mm |

| amandla okuncamathelisa (indlela yeletiyisi yomqolo) | ISO 2409 | 0 inqanaba |

| ukugoba | ISO 1519 | 2mm |

| ukuqina kwepensile | I-ASTM D3363 | 1H |

| uvavanyo lokutshiza ityuwa | ISO 7253 | > iiyure ezingama-500 |

| uvavanyo olushushu kwaye lufumile | ISO 6270 | > 1000 iiyure |

| ukumelana nobushushu | 110℃/24 iiyure (ezimhlophe) | ugcino olubalaseleyo lokukhanya, umahluko wombala≤0.3-0.4 |

Amanqaku:

1.Olu vavanyo lungentla lusebenzise iipleyiti zentsimbi ezingqindilili eziyi-0.8mm ezinobukhulu obuyi-50-70 microns.

2.Isalathiso sokusebenza sale ngubo ingentla inokuncipha kancinci ngokuncipha kweglosi.

I-Avareji yoFundo:

9-12 sq.m./kg; Ubukhulu befilimu buyi-60 microns (ibalwe nge-100% yezinga lokusetyenziswa komgubo)

Ukupakisha kunye nokuthutha:

iibhokisi zifakwe kwiingxowa ze-polyethylene, ubunzima bomnatha bu-20kg. Izinto ezingenabungozi zingathuthwa ngeendlela ezahlukeneyo, kodwa kuphela ukuphepha ukukhanya kwelanga, umswakama kunye nokushisa, kwaye ugweme ukudibanisa nezinto zeekhemikhali.

IiMfuno zoGcino:

Gcina kwigumbi elingena umoya, elomileyo nelicocekileyo kwi-30℃, lingasondeli kumthombo womlilo, ukufudumeza okuphakathi kwaye uphephe ukukhanya kwelanga. Akuvumelekanga ngokungqongqo ukufumba kwindawo evulekileyo. Ngaphantsi kwesi simo, i powder ingagcinwa kwiinyanga ezi-6. Emva kokuba ubomi bokugcina buphinde buhlolwe kwakhona, ukuba iziphumo zihlangabezana neemfuno, zisenokusetyenziswa. Zonke izikhongozeli kufuneka zipakishwe ngokutsha kwaye zipakishwe kwakhona emva kokusetyenziswa.

Amanqaku:

Zonke ii powders ziyayicaphukisa inkqubo yokuphefumla, ngoko ke kunqanda ukuphefumla umgubo kunye nomphunga ekunyangeni. Zama ukuphepha ukudibanisa ngokuthe ngqo phakathi kwesikhumba kunye nomgubo wokugquma. Hlamba ulusu ngamanzi kunye nesepha xa kufuneka ukudibana. Ukuba ukudibana kwamehlo kwenzeka, hlamba ulusu ngokukhawuleza ngamanzi acocekileyo kwaye ufune unyango ngokukhawuleza. Umaleko wothuli kunye ne-powder particle deposition kufuneka igwenywe kumphezulu kunye nekona efileyo. Amasuntswana amancinci aphilayo aya kuvutha kwaye abangele ukuqhuma phantsi kombane omileyo. Zonke izixhobo kufuneka zibekwe phantsi, kwaye abasebenzi bokwakha kufuneka banxibe izihlangu ezichasene ne-static ukugcina umhlaba ukuthintela umbane ongatshintshiyo.

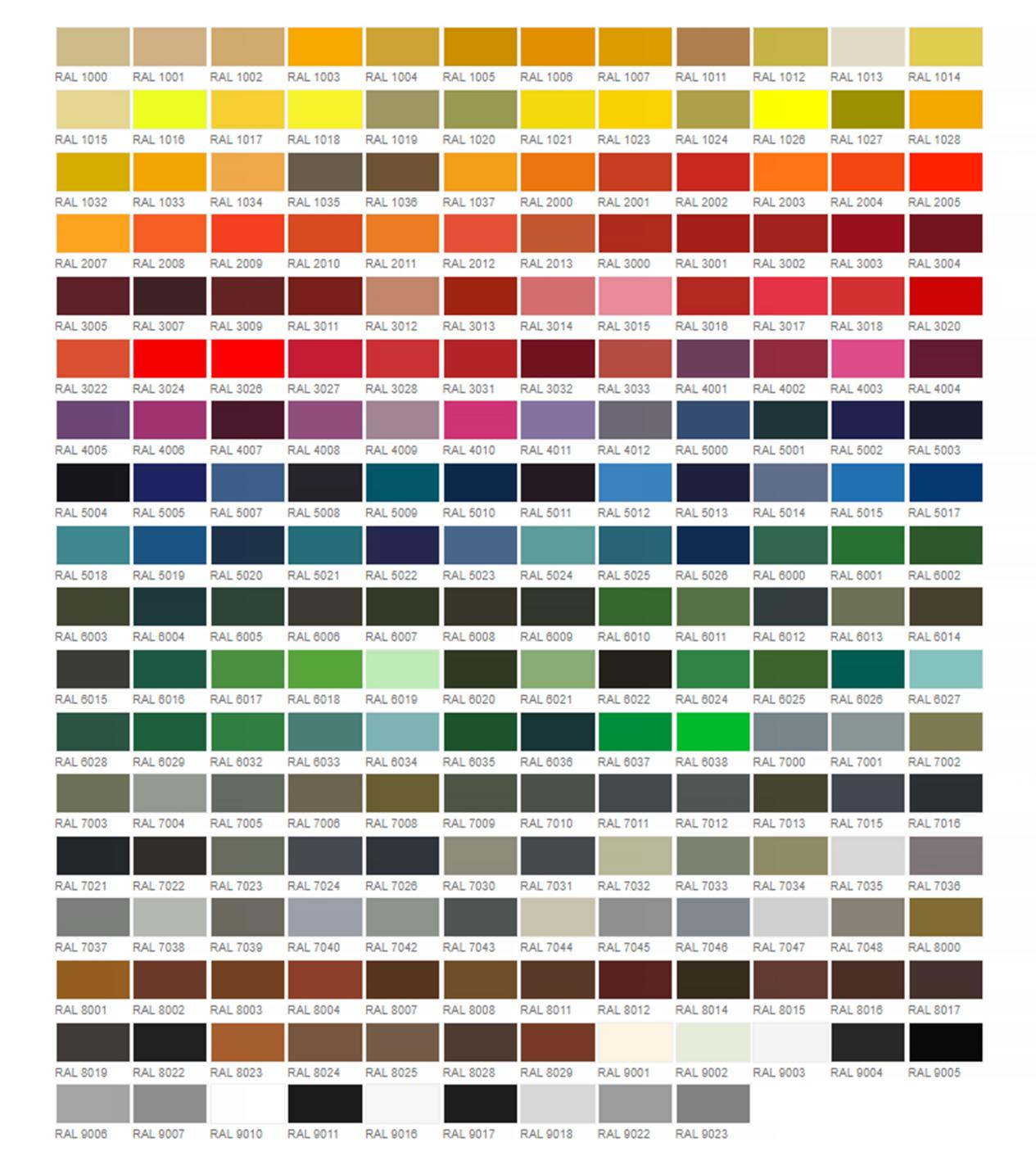

Nawuphi na umbala uyafumaneka kwiColorcom: